Sanzhuji's analysis on green sand casting2.0

6. The ability of tightly air-permeable sand to allow gas to pass through and escape is called air-permeability. The air permeability is mainly affected by the size, particle size distribution, grain shape, mud content, binder type, addition amount and the distribution of the binder on the sand during sand mixing and the compactness of the sand. For wet type single sand and surface sand, the air permeability must not only have a lower limit, but also must be strict

The grid stipulates its upper limit.

7. Wet strength molding sand must have a certain strength to withstand various external forces. The strength of molding sand is expressed by the stress value when a standard sample of molding sand is destroyed under the action of external force. Commonly used

The unit of measurement is megapascals (MPa) or kilopascals (kPa). In wet casting, the wet compressive strength of sand and gravel is often inspected, and some also measure wet shear strength and wet tensile strength. For green sand for general machine modeling, the wet pressure strength is usually controlled to be between 0.06^0.12MPa, and for green sand for high-density modeling, the wet pressure strength is often controlled at 0.09^0.20MPa. The surface hardness tester is often used to measure the hardness in production. Reflects the compactness of the molding sand and the surface strength of the mold.

8. Flowability The ability of molding sand to move relative to each other along the pattern and sand under the action of external force or its own weight is called fluidity. Good fluidity molding sand can form a cavity with uniform compactness, no local looseness, clear outline, and smooth surface, which helps prevent mechanical sand sticking and obtain smooth castings. In addition, it can also reduce the labor intensity of modeling compact sand, improve productivity and facilitate the mechanization of modeling and core making processes.

8.1 Use a wet hardness tester to measure the difference in hardness between the two end faces of the standard sample. The smaller the difference in hardness, the better the fluidity of the molding sand.

8.2 Place a semi-circular metal block with a height of 25mm in the standard cylindrical sample, and determine the hardness difference between the two planes of the stepped sample

8.3 Determine the height of the sample impacted in the annular cavity molding sand sample tube on the bottom side

8.4 Side hole method: Determine the side of the cylindrical sample when impacting the sand sample. The quality of the sand extruded in the 12mm small hole

8.5 Specimen quality method: that is, to compare the quality of the specimen after measuring the compaction rate. The larger the bulk density, the better the fluidity.

9. Mold releasability, deformation, toughness and crushing index The releasability of molding sand is the performance of whether it is easy to damage the pattern or the separation of the template and the sand mold when the mold is drawn, and whether it will fall off. The deformation of the molding sand is usually measured by the strength testing machine while measuring the compressive strength of the molding sand, and a dial gauge is used to measure the deformation (the amount of height reduction) before the sample is broken. From this, the toughness of the molding sand can also be calculated, that is, the green compressive strength (MPa) of the molding sand (cm) and the amount of deformation (cm) multiplied by 1000 to express the toughness (MPa. cm).

10. The characteristics of old sand and its treatment It takes about 5~10t molding sand to produce 1t wet castings. In actual production, when preparing molding sand, try to reuse old sand (ie, reused molding sand). This is not only economical, but also important. It is also a need to protect the environment and prevent public hazards. It can be seen that when mixing sand, it is necessary to add new sand, bentonite, coal powder, water and other materials to the old sand in order to make

The performance of the mixed molding sand meets the requirements. After the castings are boxed, there are often iron blocks, iron beans and sand blocks in the sand. Therefore, the old sand has to go through multiple magnetic separations, crushing agglomerates and sieving to remove the debris. It should also undergo a dust removal treatment to reduce the dust content in the old sand, and then reuse it. In addition, a series of measures must be taken to reduce the temperature of the old sand.

11. Green sand mixing process The commonly used sand mixers in production include roller type, balance wheel type, rotor type and so on. The high-efficiency rotor sand mixer used in some mass-produced foundries is a high-productivity continuous sand mixer. With the continuous upgrading of casting equipment, the new GS high-efficiency rotor sand mixer has begun to be recognized by the foundry. The usual feeding sequence is to first mix the recycled sand and dry materials such as fresh sand, clay powder, coal powder, etc., and then add water to mix to the required moisture. For green sand, it is necessary to strictly control the amount of water added during sand mixing.

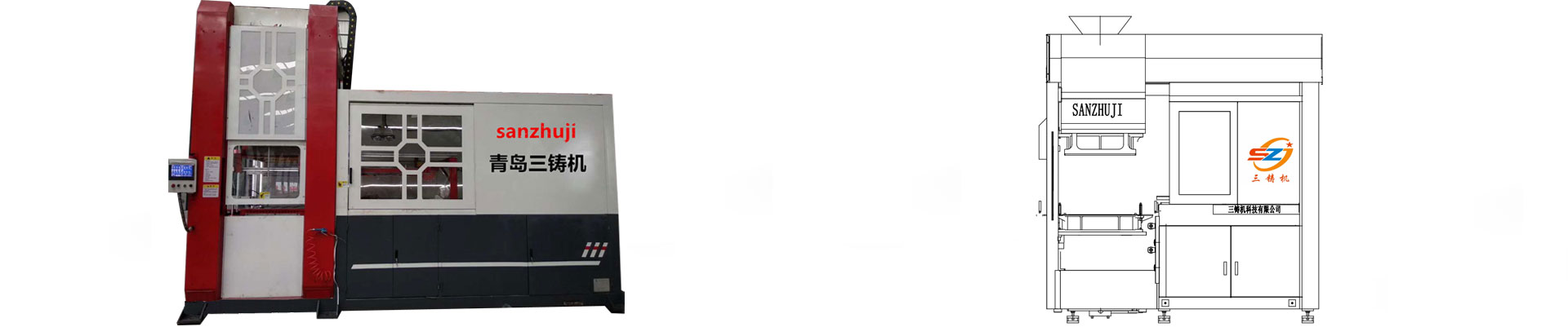

Qingdao Sanzhuji Equipment Manufacturing Co., Ltd. specializes in the production of Green Sand Molding Line,Self-hardening sand molding line,foundry machines,Sand molding machine,Sand casting equipment,sand mixer,GS high efficiency rotary mixer,Resin sand mixer,no-bake resin sand mixer,Jolt squeeze molding machine/Jolt-squeezing moulding machines,Multi- Piston Moulding Machine/Hydraulic multi-piston moulding machine,sand casting molding machine,sand reclamation equipment,foundry molding machine,flaskless moulding machine,shot blasting machine,dust collector,according to the amount of old sand recovered Carry out plan customization, and provide sand reclamation equipment installation, commissioning, and training. Welcome guests to visit the factory.