Argentina Jolt-squeezing molding machines

143 Jolt-squeezing moulding machines

working desk size: 560×465 mm

Extrusion stroke: 120 mm

productivity: 30-40 molds/hour

Compressed air pressure:0.6Mpa

Jolt-squeezing moulding machines, which can be used in automated green sand casting lines or individually, 40-60moulds/h, divided into cope and drag, so they need to be used in pairs, using air cushion type vibration compaction, flat plate compaction sand, sand hardness in HB80-90 on average.

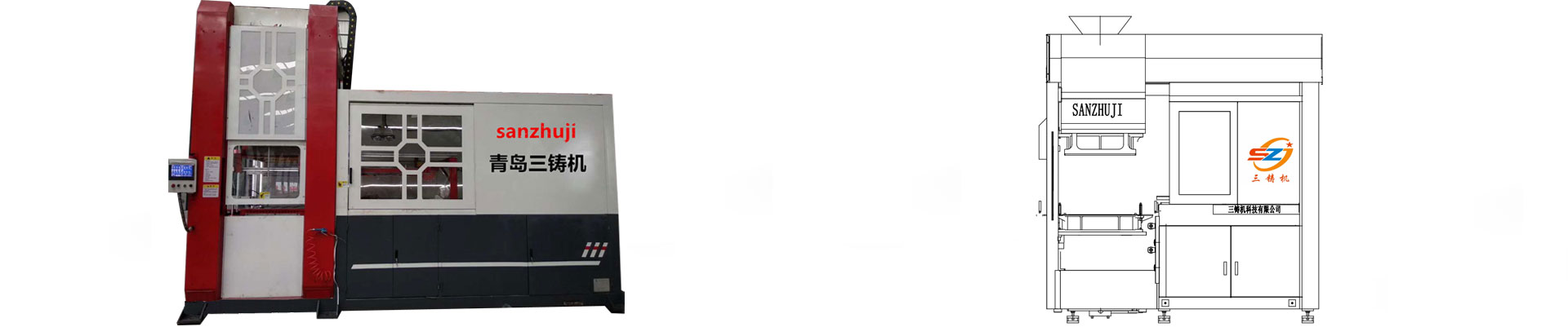

The structure of the machine is optimized, and the fuselage adopts a square box basket structure, which greatly improves the rigidity of the fuselage. The machine adopts the micro-seismic compaction molding process, which can greatly increase the compaction strength so that the hardness of the sand box can reach above HB90, and the surface roughness is increased by one level to stabilize the product quality. The shock part of the machine is equipped with a buffer spring, which effectively reduces the impact of the machine on the base. The machine mold mechanism adopts air cylinder, crank, connecting rod, and synchronous shaft to realize synchronous ejection. The control part of this machine adopts pneumatic components to realize the overall function, simple operation and convenient maintenance. The machine is easy to operate, can see the sand mold situation, and the operating procedure can be humanized, which effectively improves productivity.

Micro-seismic compaction molding machine The structure of the machine is optimized. The body adopts a square box basket structure, which greatly improves the rigidity of the body. The machine adopts the micro-seismic compaction molding process, which can greatly improve the compaction strength so that the hardness of the sand box can reach above HB85, and the surface roughness is increased by one level to stabilize the product quality. The shock part of the machine adopts air cushion micro shock to effectively reduce the influence of the machine on the foundation. The south ejection mechanism uses cylinders, cranks, connecting rods, and synchronous shafts to achieve synchronous ejection. The control part of the machine adopts pneumatic components to realize the overall function, simple operation and convenient maintenance. The machine is easy to operate, can visualize the sand mold situation, and the operating procedure can be humanized, which effectively improves productivity.

Although many sophisticated moulding machines are used in moulding process in green sand casting. Jolt squeeze moulding machine is still very popular for below advantages:

1. Cost saving moulding machine for green sand casting. Jolt squeeze molding machine can be used for manual casting and semi-automatic casting line. Cost is just 1/10 of flaskless moulding machine.

2. Bigger moulds size. It is better to use jolt and squeeze machine for moulds > 700x600mm and height >250mm.

3. Uniform and rigid moulds achieved by high frequency, low amplitude jolting with high dynamic squeeze force for uniform.

4. Maintenance and operator friendly with Heavy duty lifting cylinder, Reliable pneumatic parts, and Panel mounted push button.

Qingdao Sanzhuji Equipment Manufacturing Co., Ltd. specializes in the production of Green Sand Molding Line,Self-hardening sand molding line,foundry machines,Sand molding machine,Sand casting equipment,sand mixer,GS high efficiency rotary mixer,Resin sand mixer,no-bake resin sand mixer,Jolt squeeze molding machine/Jolt-squeezing moulding machines,Multi- Piston Moulding Machine/Hydraulic multi-piston moulding machine,sand casting molding machine,sand reclamation equipment,foundry molding machine,flaskless moulding machine,shot blasting machine,dust collector,according to the amount of old sand recovered Carry out plan customization, and provide sand reclamation equipment installation, commissioning, and training. Welcome guests to visit the factory.